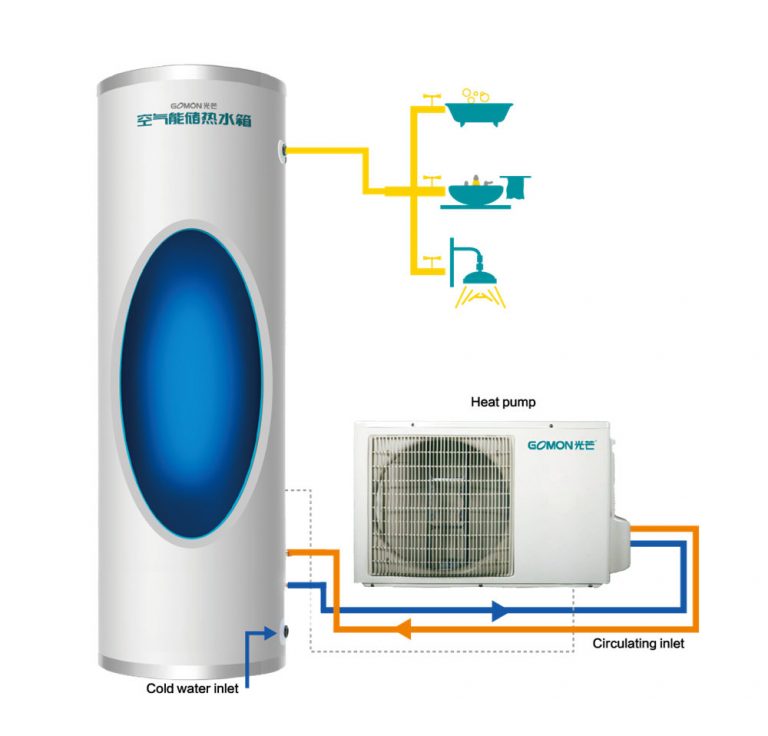

Descripción del producto

El depósito de agua con bomba de calor sin serpentín es un producto revolucionario diseñado para proporcionar soluciones de agua caliente eficientes y fiables sin necesidad de los sistemas de serpentín tradicionales. Este innovador depósito utiliza una avanzada tecnología de bomba de calor para extraer el calor ambiental del entorno, reduciendo significativamente el consumo de energía y los costes de funcionamiento.

El depósito de agua está diseñado para soportar 280.000 ciclos de pruebas de impulsos antipresión y antifatiga, lo que garantiza una larga vida útil de todo el sistema.

Parámetros técnicos

| Modelo de producto | 150L | 200L | 300L | 400L | 500L |

| Diámetro interior del depósito (mm) | Φ370 | Φ426 | Φ480 | Φ610 | φ610 |

| Diámetro exterior del depósito (mm) | Φ470 | φ520 | Φ580 | Φ710 | φ710 |

| Presión nominal del depósito (mpa) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Presión nominal del intercambiador de calor (mpa) | 3 | 3 | 3 | 3 | 3 |

| Altura total (mm) | 1530 | 1530 | 1750 | 1510 | 1860 |

| Superficie del intercambiador de calor (m2) | 1 | 1 | 1.2 | 1.5 | 1.5 |

| Espesor del aislamiento (mm) | 50 | 47 | 47 | 50 | 50 |

| Peso (kg) | 59 | 70 | 87 | 120 | 144 |

Descripción detallada

Alta sensibilidad con marca de agua aprobada

Válvulas de alivio de temperatura y presión es adecuado para la instalación en el calentador de agua solar a presión, calentador de gas, calentador de agua eléctrico, calentador de agua de combustible, calentador de agua con bomba de calor, calentador de función sensible, etc diversos tipos de calentadores (como la caldera) y recipientes de agua caliente. La válvula se abrirá a la temperatura establecida (99℃) y la presión (7bar) para proteger el depósito de agua.

GOMON esmalte recubierto tanque interior se aplica BAOSTEEL placa de acero esmaltado especial y América Ferro esmalte en polvo. Se produce mediante procesos avanzados que incluyen la tecnología flexible de laminado CNC, la soldadura automática por plasma de América y la tecnología de esmalte laminado de Alemania. Pasa 280.000 veces las pruebas de impulso de presión, con un buen rendimiento de anti-presión, anti-fatiga, anti-ácido, anti-álcali, anti-corrosión y anti-corrosión de agua caliente, lo que garantiza su vida útil.

GOMON esmalte recubierto tanque interior se aplica BAOSTEEL placa de acero esmaltado especial y América Ferro esmalte en polvo. Se produce mediante procesos avanzados que incluyen la tecnología flexible de laminado CNC, la soldadura automática por plasma de América y la tecnología de esmalte laminado de Alemania. Pasa 280.000 veces las pruebas de impulso de presión, con un buen rendimiento de anti-presión, anti-fatiga, anti-ácido, anti-álcali, anti-corrosión y anti-corrosión de agua caliente, lo que garantiza su vida útil.

Aplicación